- About

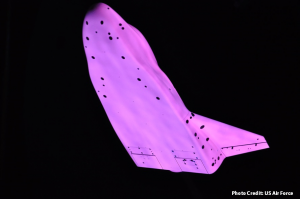

- Pressure & Temperature Sensitive Paint

- Instrumentation

- Shear Sensors

- Velocimetry

- Nuclear Division

Innovative Scientific Solutions, Inc.

ISSI supports the US Dept. of Defense, US Navy, NASA, National Institutes of Health, and other federal customers, as well as U.S. industry and academic laboratories. We work with government and industry laboratories in Europe, Asia, and South America, as well as academic organizations worldwide.

Contact

Telephone: +1 937 630-3012

FAX: + 1 937 630-3015

E-mail: [email protected]